Location:HOME > INFO CENTER >

Toothbrush manufacturing, electric and manual

Date:2021-11-26 15:41

A toothbrush is exactly the item that no person can do without. There are a large number of oral care brushes on the market today - from ordinary plastic to electric, the number of functions of which is constantly increasing. Advanced models of electric brushes have several brushing modes, record the time and quality of cleaning your teeth, they come with numerous replaceable attachments. However, traditional (so-called "manual") brushes are also very diverse.

There are ordinary budget brushes, brushes for sensitive teeth and gums, brushes with comfortable handles and bendable heads, with bristles indicating the degree of wear, etc. Additional devices and accessories are produced for toothbrushes. These include, for example, special terminators or sterilizers for the treatment of bristles. In the first case, the brushes are placed in a tank, where they are treated with water vapor, which destroys all dangerous germs and bacteria. In devices of the second type, the bristles are sterilized using ultraviolet radiation.

There are also more innovative products that are still unknown in our country and therefore are of great interest to entrepreneurs. For example, the Canadian company World Centric recently released a brush called the Compostable Toothbrush. Unlike standard toothbrushes, the products of the Canadian brand are made from a material based on safe and quickly recyclable plant materials, registered under the trade name Ingeo. The latest generation of toothbrush has already been certified by the American Society for Environmental Materials and Technologies for the Future (BPI).

Nowadays, the international market of toothbrushes is dominated by the products of sever large manufacturers. The leaders among them are the concern Colgate - Palmolive, Procter & Gamble, Johnson & Johnson, Oral -B Laboratories, Acorn International Group, Amigo International, GlaxoSmithKline, Medinova.

Undoubtedly, Western toothbrush manufacturers dominate in this market segment, however, some China companies are actively promoting their products. For example, Xiaomi's electric toothbrush brand Soocas is known for its high cost performance.

A typical toothbrush consists of several parts: a head with bristles, a handle, and a “neck” that connects the two. Toothbrush bristles used to be made from pig bristles, which had many disadvantages. Modern toothbrush manufacturers use, as a rule, artificial fibers (for example, nylon) for making bristles. The bristles of a toothbrush can differ in thickness (which directly affects their rigidity), different processing of the tips, mobility, height (the optimal height is about one centimeter).

There are the following types of brushes, depending on the degree of hardness of the bristles: very hard, hard, medium, soft and very soft. This designation is rather arbitrary, since there is no single criterion for the rigidity of brushes. Manufacturers use bristles of different diameters in their products, while indicating the same degree of stiffness, which is the reason for this confusion. So, very soft brushes include products with a fiber diameter of about 0.15-0.18 mm, soft - up to 0.2 mm, and medium-hard brushes - up to 0.22 mm.

Soft brushes are intended for cleaning milk teeth (for children), teeth with thin enamel and for inflammatory diseases of the periodontal and oral mucosa. Thin and soft bristles will not damage the enamel or injure the mucous membrane.

Stiff and very stiff bristles are used for cleaning teeth with matured enamel, which are prone to increased formation of mineralized and non-mineralized plaque. Most modern toothbrushes are combined, that is, bristles of different hardness are used in one product. In most cases, the anterior bristles are made stiffer and shorter because they are designed to effectively clean the chewing surfaces of the teeth. The lateral setae (peripheral) are usually softer and longer, as they touch the gums, penetrating relatively deep into the so-called gingival groove. Bristles of varying degrees of rigidity are usually marked with different colors.

A high-quality toothbrush must meet the established standards in a number of its parameters. The procedure for the creation, production and sale of such products is determined by the approved regulatory and technical documentation. For example, materials and components that make up toothbrushes on sale must comply with GOST 6388-91.

Toothbrushes are manufactured using a similar technology as conventional ones, but using special equipment. The working part of a toothbrush can be made of treated (bleached) pig bristles (currently this material is used very rarely) or synthetic fibers. Synthetic bristles are available in most cases with a diameter of 0.15-0.8 mm and can be dyed in various colors.

Unlike natural bristles, which were previously used, artificial fibers are smoother and have no pores. For this reason, they are considered the most hygienic. Although some synthetic materials are highly abrasive, this can damage the enamel of the teeth. Therefore, manual and electric toothbrush manufacturers are trying to correct this disadvantage by combining the advantages of natural and artificial bristles, getting rid of their disadvantages. For the production of pads and handles of toothbrushes, plastic is used (in most cases, injection molded thermoplastics). The most common copolymers of styrene grade MCH. To fasten the bush of the working part, a nickel silver alloy of the MNTs brand and a crimped nickel silver wire are used.

The manufacturing process of toothbrushes consists of the same operations as the production of any other type of these products, and includes the preparation of pads, preparation of the pile, planting the bushes of the pile and finishing the products. The shoe of a toothbrush is usually one-piece with closed blind holes. It is made together with a polystyrene or polystyrene copolymer handle.

The process looks like this: small plastic balls using a vacuum are drawn into an automatic molding machine, where they are melted into a thick mass, which merges into a metal mold for ten brush handles with 56 holes. Then the colored rubber balls are melted. The liquid rubber comes into the same mold as the handle blanks. Using a press, the rubber pads are attached to the base. Somewhat less often, translucent plastic is used for the production of toothbrush handles. The automatic equipment produces ten handles (one mold) every 35 seconds.

The sockets in the blocks are drilled in straight, even rows or at intervals of two to three rows in length, which allows you to achieve better cleaning of the teeth. There are two main types of nests for pile bushes: straight to a certain depth or with an inclination to one or two sides.

Synthetic bristles, unlike natural ones, are supplied to production in a ready-to-use form. Polyamide (nylon) of various degrees of rigidity is simply cut to the required dimensions and knitted into bundles. The height of the toothbrush bush is 8 to 12 mm. To "plant" a bush of small diameter pile, which is used for such products, an anchor method is used. A small tuft of bristles of 22-24 bristles is fixed in the nest with a piece of metal tape threaded into the loop. The end of this tape is pressed into the wall of the seat under pressure.

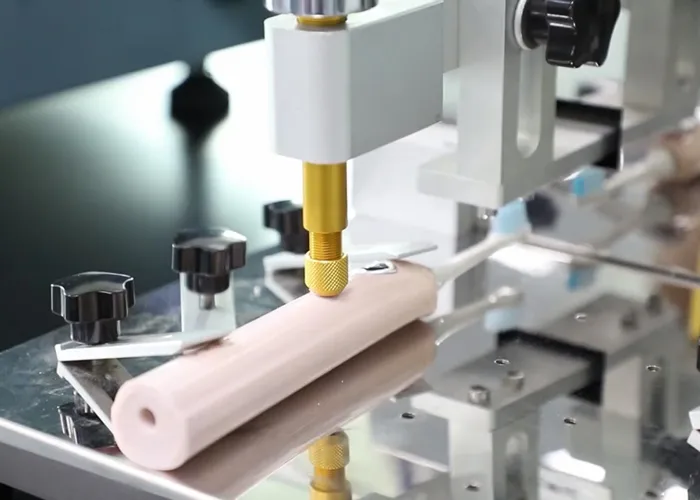

Thus, individual tufts of bristles are hammered into the holes of the head with a special copier and held in them by means of metal plates. The machine fills 900 holes within one minute. The bristles of various lengths are then cut with the machine blades. Finally, the rotating diamond-coated discs grind the edges of the bristles, giving them the desired shape (straight or curly) and appearance. The product quality is also selectively checked by the machine. Several samples are selected from the batch, the bristles of which are tested for fastening strength. If the test samples have passed the test with dignity, then the entire batch is sent to packaging.

Ready-made toothbrushes are individually packed in high or low pressure polyethylene, polyethylene film, cellulose film, polypropylene or impact-resistant polystyrene (boxes for storing and carrying brushes).

Modern toothbrushes have handles of various shapes, which allow the shoe to move better and fit more comfortably in the hand, a rounded shoe, and a curly haircut. All this helps to ensure the best cleaning of the teeth and to avoid gum injury. There are also travel toothbrushes that can be folded in half compactly thanks to the foldable handle.

So, to open your own production of toothbrushes, you will need special equipment and premises for its placement and storage of finished products. For small-scale production, two-axis or four-axis tufting machines are suitable. They are compact, efficient enough and reliable.

The lines include filling machines (filling speeds of about 850-900 beams per minute) and blister packing machines. When choosing filling machines, pay attention to the fact that the stacking magazine for the brush bodies can be changed in length and height. In this case, you will be able to fill the enclosures of any shape and size. The brush bodies are fed to the drum automatically. It is desirable that such equipment has a continuous mode of operation, without downtime.

Some machines reduce the speed of rotation of the drum in the interval between the delivery of the finished brush and the arrival of the new workpiece. Most machines work with a 35 x 45 mm hole field and are suitable for stuffing bodies with straight brush head and holes cast in parallel with a maximum inclination of 10 ° C or with radial tufts on a hole field of 8.10 or 12 degrees wide. Please note: for an additional fee, the equipment can be equipped with various options and safety devices that automatically stop the machine if something goes wrong (wire stuck, no compressed air, stuffing tool clogged, etc.). Possible error and problem messages are shown on the color display.

A used complete automatic line for filling, finishing and packaging toothbrushes, which includes two brush planters, a transport vehicle for packed brushes, an automatic finishing machine and blister packers, will cost around 27.000$. To accommodate it, an area of about 50 square meters is enough. meters plus storage space.

6-10 operators are enough to service a small automated line. In addition, you will need technologists, equipment repairmen, designers (to develop the design of the product itself and its packaging), marketers and brand managers, advertising managers, accountants, lawyers, purchasing managers.

Toothbrush manufacturing is considered a lucrative business. According to numerous business plans, its profitability reaches 120-160% (subject to placing orders in Chinese factories). Such calculations of profitability are offered by China companies that produce brushes for outsourcing in China. And such an overwhelming majority not only in China. There are relatively few toothbrush factories in the world, and the share of contract manufacturing among global manufacturing companies ranges from 40 to 100%.

The few China companies that have their own production facilities are forced to admit that the profitability of this business turns out to be much lower than expected. Even after a year and a half from the beginning of their work, they cannot reach the level of self-sufficiency. Their annual turnover is about 2.000.000$, with about 75% of them coming from China, and the remaining 25% from the CIS countries. Despite the high quality of China products, China manufacturers cannot compete with foreign companies.

One of the main reasons for this is the reluctance to invest in advertising. With a production volume of about 100,000 toothbrushes per month, they could recoup their entire investment in the first 6-8 months of operation if they could sell that number of products. But consumers are distrustful of the unknown China product with such a huge amount of widely advertised Western products. But it is only possible for those enterprises that produce at least 500-700 thousand items per month to push global brands a little on the China market. Of course, without large investments in advertising and promotion of your products, you should not count on success.

In addition, experts advise such enterprises to expand their product range, also releasing toothpaste, mouthwash, breath fresheners, dental floss, etc. Conducting massive advertising campaigns is one of the main conditions for survival in such a highly competitive environment.

The main distribution channel for conventional toothbrushes is large retail chains. According to Nielsen, they sell about 33.5% of brushes in kind. Specialized perfumery and cosmetic retail accounts for 22.6%, pharmacies - 9.3%, small retail stores - 17.5%, open markets - 11.4%, and hardware stores - 5.7%. But if we are talking about the sale of oral care products, then most of them (40-50%) are sold through pharmacies. The remaining 25-30% are sold in stores of various types. It is very difficult for a new product to get into the stores of the largest chain companies, therefore, most of the manufacturing companies at the beginning of their activities cooperate with individual retail stores, pharmacy and small regional chains.

As a professional manufacturer of electric toothbrush and oral irrigator / water flosser, Shenzhen Relish provides various types of electric toothbrush wholesale and OEM customized services. You can also wholesale water flosser from Relish at factory price. We can provide you highly competitive prices and look forward to working with you.

Post a comment

- All comments(0)

No comments yet, come be the first!

日本語

日本語 Español

Español Deutsch

Deutsch 中文

中文