How electric toothbrushes are made? What is the internal structure?

When it comes to electric toothbrushes, it seems that they are popular in recent years? But the first electric toothbrush actually appeared as early as 1954. At that time, the Swiss doctor Philippe-Guy Woog invented this electric toothbrush (knocking on the blackboard! The electric toothbrush was invented to brush teeth more conveniently), and it was named Broxodent, as shown in the following figure.

Different from the current universal wireless style, the newly invented electric toothbrush can only be used after being plugged in electricity. It is described as a kite with a wire being pulled, which cannot be too far away from the socket. Until the 1960 s, only GE introduced the first wireless electric toothbrush, and it was not until 1992 that the current common sonic electric toothbrush came into being ~

Clean by sound wave?

The so-called sonic electric toothbrush, this "acoustic wave" does not mean to clean teeth by ultrasonic wave, but the vibration frequency generated by the toothbrush has reached the frequency of acoustic wave, that's why people call it "sonic electric toothbrush 」. In the working process of the electric toothbrush, the high-speed motor Conducts kinetic energy to the transmission shaft, making the brush head produce a high frequency oscillation with a small amplitude perpendicular to the brush handle.

When you brush your teeth, besides the cleaning power of the brushing itself, you also increase the viscosity of the liquid deep into the teeth through high-speed vibration, thus the dental plaque is stripped and cut off from the teeth ~ as can be seen from the following figure, the toothbrush with high-speed vibration exerts acting force on the teeth through the impact of water flow, and deeply cleans the teeth. There is no need to say the cleaning ability. This puff bubble, vibration frequency and watering ability are also very strong.

Well, the principle part is probably like this. Next, we will talk about the main manufacturing process of electric toothbrush step by step.

Overall design

The first is to design the shape and structure of the electric toothbrush: Take the toothbrush which I use as an example. In terms of aesthetics, the style, material, color matching and functionality of the Shell should be designed, including the structure of each component inside, such as the arrangement of circuit board, motor, battery and charging coil inside. As for the industrial design of the whole machine, it is balanced, beautiful, portable and easy to use, and none of them is necessary!

Resin shell

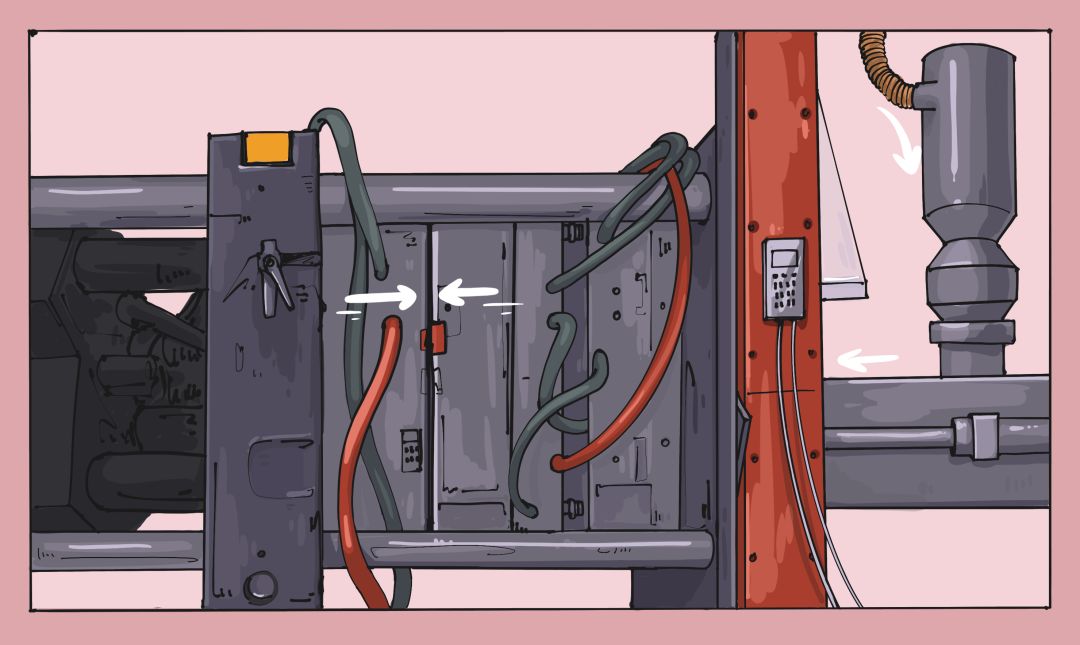

The shell and component bracket of electric toothbrush are made of ABS plastic, which is generally called "Resin". This material is hard, anti-fall and durable, it can be regarded as the utility material of the elder level. The manufacturing process is the high temperature injection molding that we are very familiar with: first melt the plastic particles, then inject them into the mold through the injection molding machine, and wait until the cooling and curing, the shell of a toothbrush body is finished ~

Next, do a dust removal cleaning on the inner cavity of the shell, then use the camera to shoot the interior, and analyze whether there is any residue through the linkage computer. The right side of the picture below is the picture taken by the high-speed camera on the inside of the brush body ~

Because the circuit board and motor will be put in later, it is very important to keep the interior of the toothbrush body clean! Otherwise, in the process of use, although the most worrying thing is to be infiltrated and corroded by water from the outside (sealing performance), if there is dust before sealing, it will directly affect the performance of the electric toothbrush...

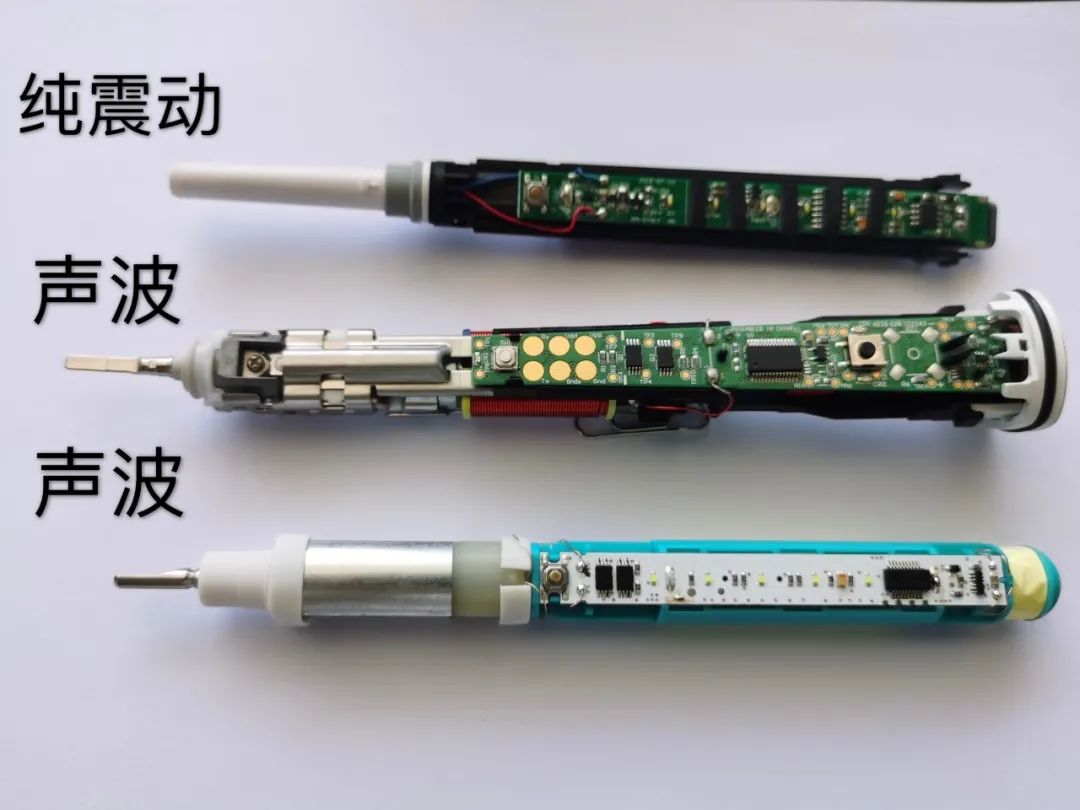

Magnetic levitation Motor since the rotating speed of the sonic toothbrush needs to reach 31000 times per minute, the current mainstream sonic toothbrushes, look at the picture below, no matter hundreds of thousands of foreign or 200 or 300 domestic ones, all adopt magnetic levitation motors.

The appearance on the left side of the picture below is ordinary, but in fact it has extremely profound internal strength. Zhang Sanfeng want to applaud when seeing it. The eccentric wheel motor on the right is used by the cheap pure vibration electric toothbrush on the market, which is driven by the vibration of the whole electric toothbrush, and the cleaning strength is very poor...

Under my demonstration, the permanent magnet of the magnetic levitation motor can easily absorb the iron spoon.

The principle is that after the motor is powered on, the rotor in the magnetic levitation motor rotates to induce the magnetic field, and then the rotor is suspended in the middle of the magnetic field through the interaction of the permanent magnet. There is no mechanical friction during operation, therefore, the stability is relatively strong and the output power is relatively large. Finally, the kinetic energy is transmitted to the head of the toothbrush through the transmission shaft, and when it is transmitted to the teeth, the cleaning effect will be very good ~

Control and power supply We skip the production of circuit board, because now this small and micro integration, electric toothbrush manufacturers are also customized from specialized circuit board manufacturers for direct use... but the function still needs to be introduced ~ the PCB circuit board inside the electric toothbrush stores the control program of the electric toothbrush, it controls different speeds and frequencies of the motor. When it comes to our manual operation, the simple one may only adjust a few intensities, while the complex one also stores functions such as automatic timing and reminding changing areas to brush teeth. Then, the rechargeable battery used for power supply is added, if you want to make wireless charging, of course you have to add a charging coil at the bottom of the toothbrush.

Assembly seal These components are installed on the inner bracket in sequence and fixed. Of course, the sealing rubber ring is also prepared, and then put into the main shell of the electric toothbrush.

Next, we need to seal the main body of the toothbrush. The waterproof work is done well, and the sealing process is indispensable ~ the following toothbrush is an integrated bottom, packaged from the top. It is easy for us to put the electric toothbrush in the wet wash basin or toilet. In this way, even if water is formed at the bottom, it will not have any effect.

Usually, one of the key points of purchasing electric toothbrushes is to find comments to see if anyone complained that the toothbrush is flooded or the battery is leaking, which is the biggest threat to the service life of the product, otherwise, you have used it for only a few months. Good guy, experience the feeling of heartache directly...

Food grade brush head

After the main part is finished, let's look at the manufacture of brush head and bristles ~ because the brush head, Shell and bracket are the same injection molding process, the manufacturing process is omitted, and the material requirements are absolutely stricter. Although it is also ABS, as the thing that is often put into the mouth, the requirement for resin is to reach the food level (food level is used for eating, and food level is used for touching the mouth).

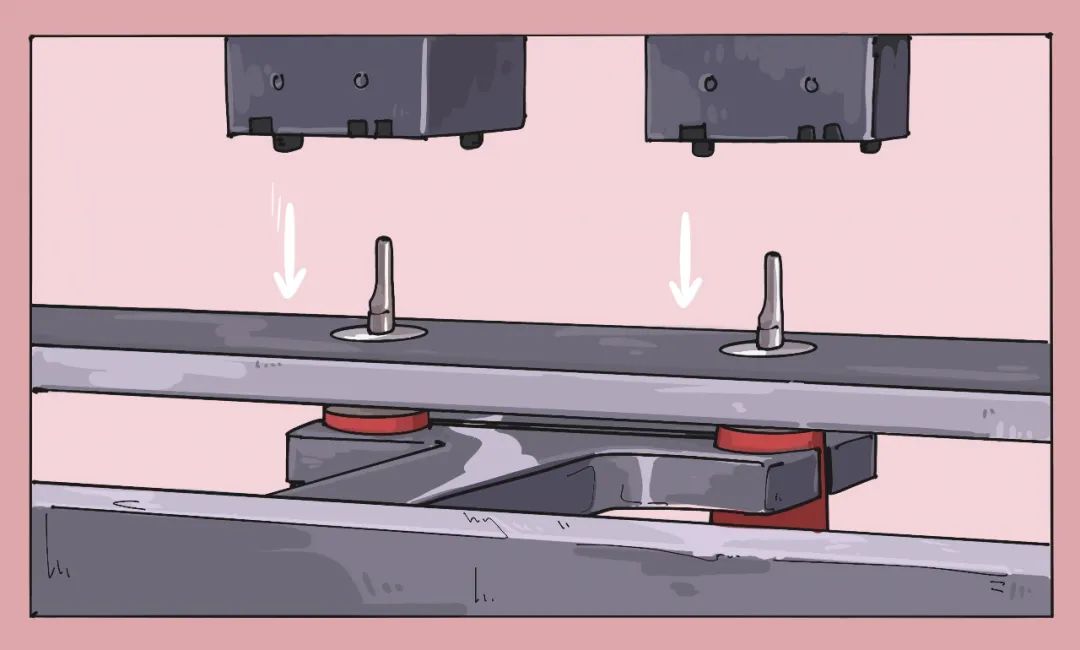

Machine hair planting

As an electric toothbrush, the most important thing is the cleaning ability. The core factor is the motor and the second is the brushing ~ The key point is the brushing manufacturing made of nylon material, which was in the 1930 s,... Invented by DuPont when the manufacturer designs and arranges the bristles, the most important consideration index is the safety of the bristles and the ability to remove dental plaque and improve the health of gums. The process of hair planting is interesting ~ fold the brushed hair in half first, and then insert it into the groove by the ultra-high speed of the machine, which combines the brushed hair with the brush head.

Stuck brushing

The key point is that there is a "small card" when the brushing is folded in half, which is used to fix the brushing in a single groove. It is deeply rooted. Nowadays, most manufacturers choose non-metal hair planting technology, it can avoid the problem that metals are oxidized and corroded in humid environment ~

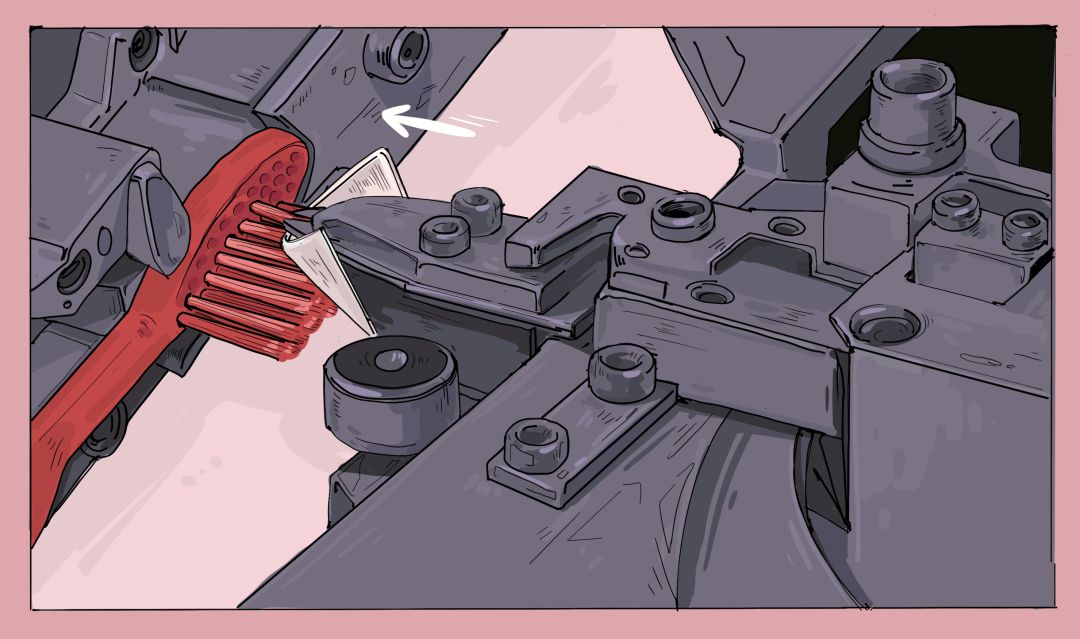

Trimming and brushing

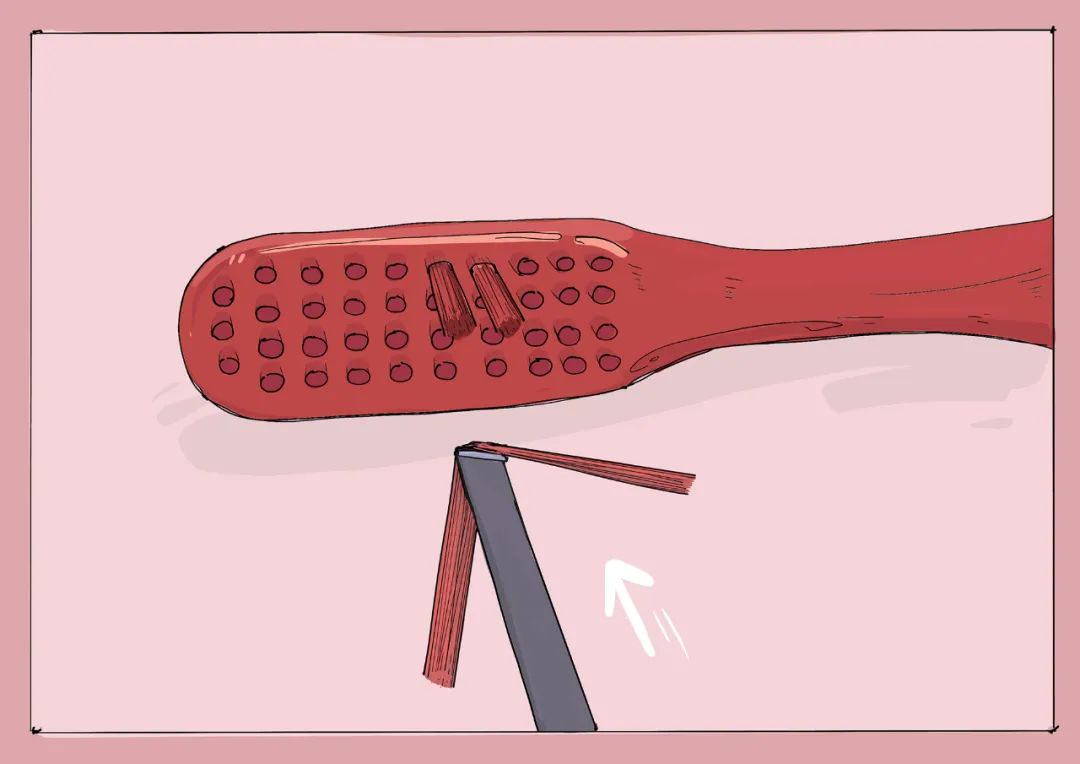

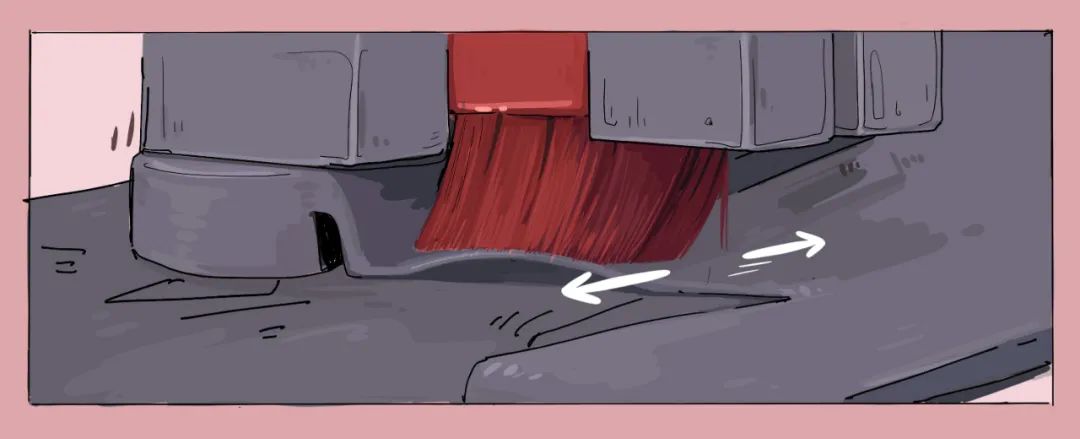

Then, according to the shape of the brush head, trim the length of the bristles as required. The contact surface of the picture below and the red bristles is actually a sharp blade, which is continuously cutting back and forth clusters of toothbrush bristles...

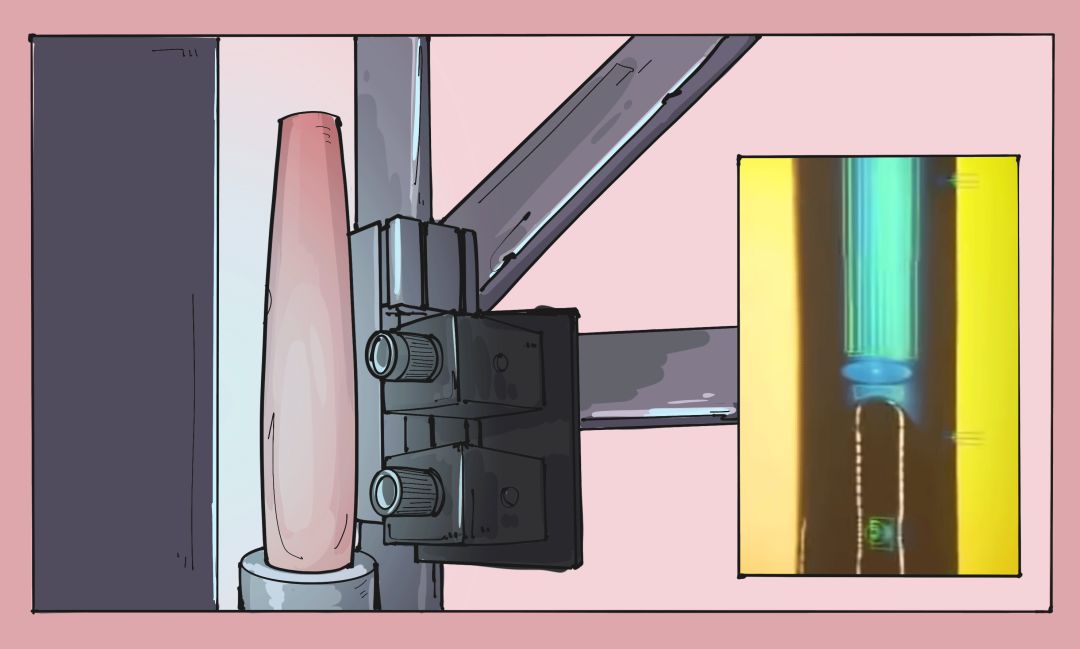

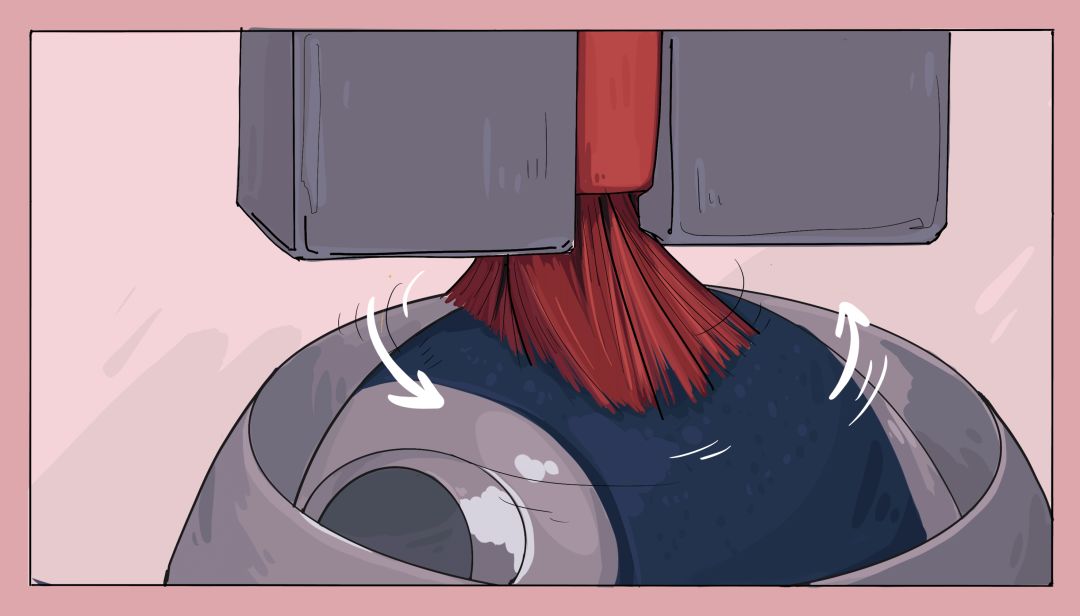

The edge of the polished round and trimmed bristles is still very rough. Now it still needs to be rotated and polished continuously until the top micro-map of a single bristles is round, which is qualified.

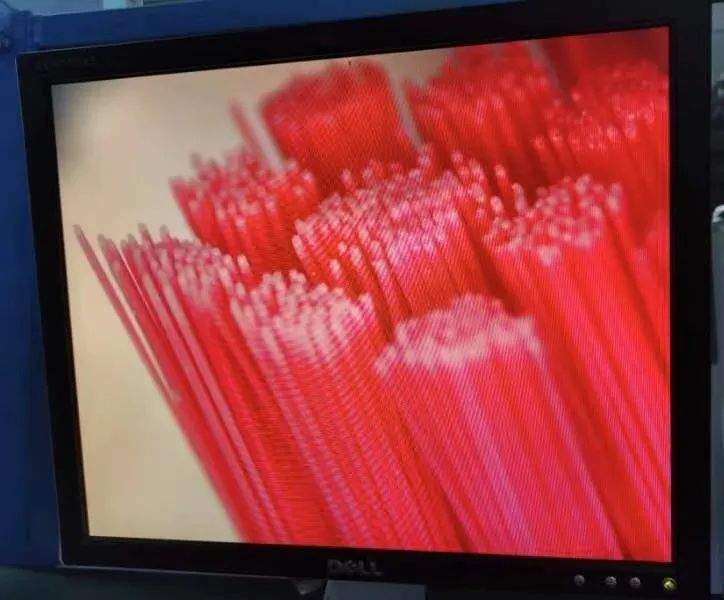

The following figure shows that workers are using machines to check whether the toothbrush hair is qualified. To adjust to the appropriate light brightness, fine-tune and zoom in the top of the bristles.

Then on the computer screen, you can observe whether the outline of the hair bundle has been polished and rounded.

Because the brushing is directly in close contact with teeth, once there is a problem with the brushing, other parts are useless no matter how good it is. Because the effect of force on brushing teeth is mutual, and the abrasion of brushing hair is also in progress, all the electric toothbrush manufacturers will let consumers use it for several months, the reason for changing the toothbrush head once.

Brushed selection

It is necessary to talk about the choice of brushing. For example, for people who are sensitive to gums, there will be tapered fiber soft brush, while those who pay attention to cleaning strength tend to cylindrical fiber. If you pay attention to the cleaning of big teeth, it is recommended to choose a small and flexible brush head, so that the effect of grooved teeth will be better after cleaning.

Put it into a storage box with the function of disinfection and charging. It can be said to be convenient and decent for traveling ~

As a professional manufacturer of electric toothbrush and oral irrigator / water flosser, Shenzhen Relish provides various types of electric toothbrush wholesale and OEM customized services. You can also wholesale water flosser from Relish at factory price. We can provide you highly competitive prices and look forward to working with you.

- All comments(0)

thuoa4727@gmail.com Comment How electric toothbrushes:Hi i am Antony from kenya and i have samething i could like you to manufacture fo

thuoa4727@gmail.com Comment How electric toothbrushes:Post a comment

日本語

日本語 Español

Español Deutsch

Deutsch 中文

中文